A while back Rosanna was riding old red and gold maxi and kept mentioning how bad her brakes were. I must admit I didn't consider her concerns to be in urgent need of attention until I had an opportunity to ride the bike myself. What she described as "doesn't brake very well" was in reality a complete lack of brakes. It was a truly hair raising experience. I tried a few times to improve the brakes by sanding down the drums, putting in new shoes, changing out the brake lines, nothing seemed to improve the situation.

So, when Rosanna hatched her plan to build a custom Pinto, I was determined that her brakes be over built. I want her to be able to stop on a dime. So while many people are adapting motorcycle disc brake setups, I thought that I would adapt a mountain bike disc brake setup. There are a few reasons for this:

A) Bicycle disc brakes are relatively cheap.

B)The calipers come in very good quality cable operated versions. My plan is to use the stock moped levers.

C) The challenge, man!

The first task was to make an insert that would replace the existing brake hub. I managed to purchase some aluminum stock from online metals for about $10. I headed down to the wizard lair and turned the insert, drilled and tapped it. This was certainly the most time consuming part of the process.

So as you can see here, I have drilled and tapped for the disc, and I have drilled and tapped the insert to keep it from spinning on the hub.

And then here you can see Rosanna's beautifully powdercoated wheel has matching mount holes.

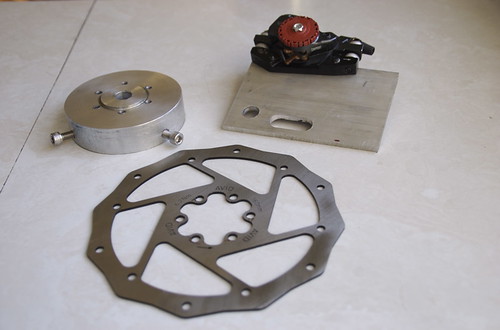

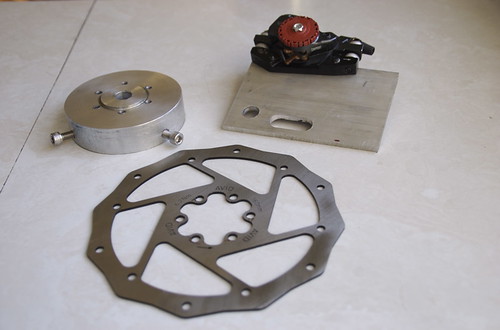

Here are all the parts. Up in the top right corner you can see the bracket I made for the caliper. The round hole mounts on the axle and the slot goes on the existing brake stop.

I still have a little bit of work to go before this wheel is complete, spacers need to be cut for the bearings and the hub insert and the brake caliper. But now that the wheel has been powdercoated we are a lot further along. Exciting!!!